The main gas pipelines are designed to transport gas over long distances. To be able to pump gas through pipelines over long distances, a significant increase in its pressure is necessary. The pressure in the main pipeline can reach 100 bar. After transporting gas to the place of consumption, it is necessary to lower it to the pressure of the distribution network, which is from 3 to 12 bar.

To lower the pressure, gas distribution stations are being built near the consumer.

There are two fundamentally different ways to reduce pressure.

1. Throttling.

Conventionally, this process can be considered isoenthalpic (h = const). In this case, a decrease in pressure occurs when the gas passes through the throttle - a constricting device. In this process, the entropy increases, the so-called loss of performance - gas with high parameters is converted to gas with lower parameters without performing useful work.

2. Turbo expansion.

This process can be conditionally considered adiabatic (s = const). Here expansion takes place in a turbine generating useful work. The enthalpy of a gas decreases, as does its temperature. The difficulty is that the temperature drop is significant, the gas at the outlet of the turbine has negative temperatures.

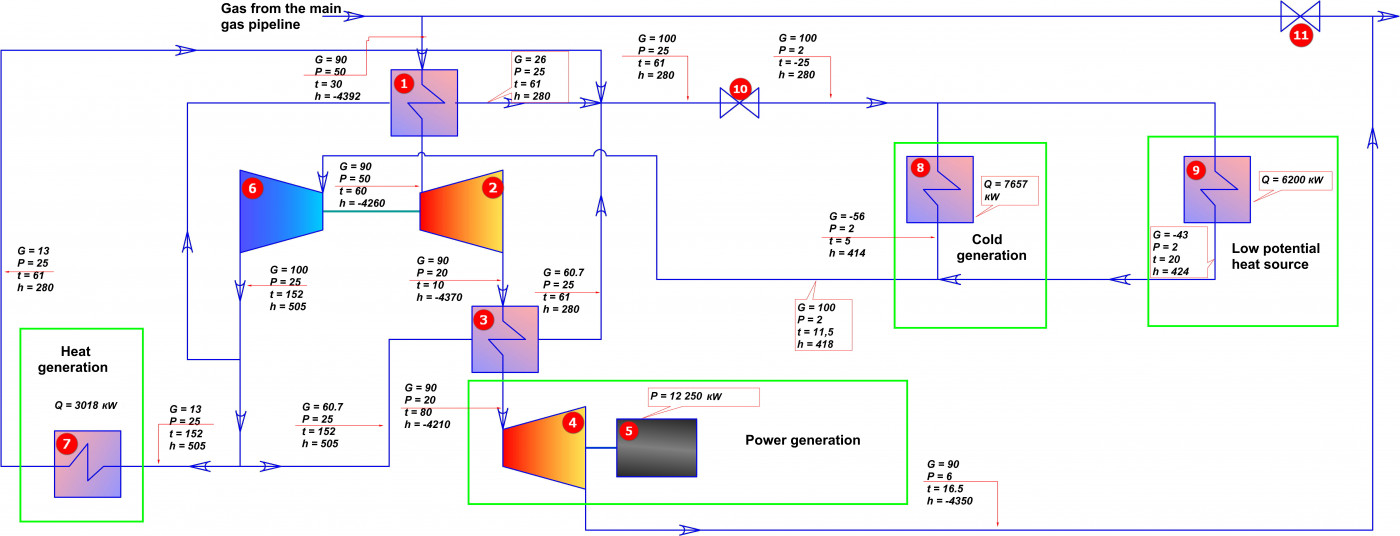

The following is a diagram of a station where gas decompression is carried out with combined production of electricity, heat and cold, as well as heat intake from a low potential source (for example, wastewater).

In the circuit 2 coolants circulate.

The first is decompressible natural gas. From the main gas pipeline, gas in the amount of 90 kg/s enters heat exchanger 1, where it is heated to a temperature of 60 °C, and then expanded in turbine 2, which serves as a drive for the compressor. At the outlet of turbo-drive 2, the gas temperature is 10 °C, its pressure is 20 bar. Then the gas is again heated in the heat exchanger 3 to 80 °C, after which it expands in the turbine to the required final pressure of the distribution gas pipeline - 6 bar. This turbine rotates the generator 5, the useful generation of electricity is more than 12 MW. Decompressed gas enters the distribution network with a temperature of 16.5 °C.

The second circuit is the refrigerant circuit R22. It is pumped through the circuit by a compressor 6, driven by a turbo-expander 2. The refrigerant consumption is 100 kg/s. It enters the compressor at a pressure of 2 bar and a temperature of 11.5 °C. In the compressor, it is compressed to 25 bar, its temperature rises to 152 °C. Part of the refrigerant (26 kg/s) is separated and sent to the heat exchanger 1, and part (61 kg/s) to the heat exchanger 3, where these flows heat the natural gas. The remaining part (13 kg/s) enters the heat exchanger 7, where heat is transferred to the consumer. This can be heating domestic or heating water, or heat for the technological needs of the station. In each of the heat exchangers, the refrigerant temperature drops to 61 °C, after which the flows are combined. The combined stream enters the throttle 10, where its pressure drops to 2 bar, and the temperature drops to -25 °C. When this stream is heated to 11.5 °C, it is possible to use almost 14 MW of cold: for technological needs (for example, refrigerated trucks), or for taking heat from a low-grade source.

The throttle 11 is designed to relieve gas pressure on the bypass line when the refrigerant circuit is disconnected.

Thus, the construction of such a station will allow for decompression of 90 kg/s of natural gas from 50 to 6 bar to obtain 12 MW of electricity, 3 MW of thermal energy and almost 14 MW of cold.

Olga Altukhova

Olga Altukhova