Throughout the history of its continuous development, mankind needed energy. At the beginning of time, its source was the muscular strength of man and animals. But soon, man turned his attention to natural forces and phenomena, which made it possible to harness the wind. Since that time, humanity has been using this natural energy. As the technological development of mankind, many mechanisms were invented to convert the energy of this renewable and free source into mechanical energy.

Improving technology has enhanced energy dependence. Especially acute the issue became during the period of industrialization. At that time, the main stake was made on the search for new sources of energy. And the discovery of oil fields made the internal combustion engine the flagship of driving mechanisms for a long historical period.

But humanity does not stand still. Modern society is actively developing and is constantly looking for affordable and environmentally friendly sources of energy. In the framework of this activity, scientists not only find new sources of energy, but also improve existing or long-forgotten ones.

Thus, in recent times, wind energy has become increasingly popular, which in its time has played a significant role in the formation and development of some European countries.

Wind power began to gain another popularity in the 70s of the last century, when the basic theories of aerodynamics were finally formed, and the use of polymer materials allowed to reduce the material consumption of structures and increase their reliability.

The use of small wind power plants often has a number of socio-economic advantages over the use of diesel generators or the expansion of an existing power system. The wind farm is smaller in size, it is a single module and it takes less time to install it than it does to expand the existing power system.

It is ironic that wind was one of the first inanimate sources of energy used by man, and it is not possible to fully realize the energy potential of wind today. The search for more profitable wind turbine designs, profiles of blades and materials for their manufacture is still ongoing.

Achieving certain successes in this field of energy contributes to the popularization of wind turbines among the population. In turn, this gives rise to large-scale production of wind turbines worldwide and can significantly reduce the prices of materials for their production.

Wind turbines are not without flaws. So, the main one is the direct dependence of its work on the wind situation in the area where the operation is planned. Without a detailed preliminary study of the site and without the availability of real data on the state of wind speed, it is impossible to choose a suitable wind turbine. This aspect forces engineers to carry out certain preparatory work to determine the wind potential of the area. And, due to the data obtained, carry out engineering calculations of a wind turbine suitable for this particular area, taking into account the necessary generating capacities.

On the other hand, the sufficient capacities of modern computer technology and the existence of formed calculation methods allow to automate this process.

The purpose of this article is to acquaint the audience with a software product that allows you to level out significant time spent on engineering calculations during the design of a wind turbine of a wind turbine with a capacity of 100 W to 100 kW.

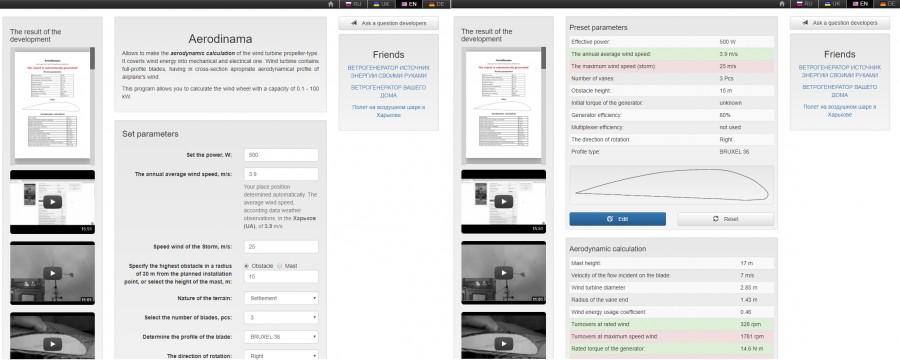

"Aerodinama" is an online resource, the web interface of which is shown in the figure.

The Aerodinama Program is based on the latest achievements in the field of wind power. The application is written in PHP programming language, and based on the calculation algorithm, it allows to design wind turbines from 100 W to 100 kW.

The version of the program under number 3.5 has a modular structure and consists of the following components (modules): geolocation, meteorology, profile characteristics, data input, aerodynamic calculation, calculation of operating modes of wind turbines, design characteristics, technical documentation.

The user interface is presented in Ukrainian, Russian, English. The default language is Russian.

Let’s consider separately the features of each module.

The geolocation module automatically determines the user's location, as well as the language locale. If the language locale of the user is not in the list of languages of Aerodinama the default language is substituted. Also, with the help of this component, the user's location is accurately determined up to the settlement.

The meteorological module is required to obtain statistical weather data, such as the average annual wind speed. Data is obtained by parsing sites with weather forecasts. Sampling is based on actual data for a period of 10 years and is stored in the local application database. After the user enters the data entry page, he will be asked to use the calculated wind speed for the automatically determined settlement, which the user will be informed about. However, the user is still able to enter this value manually.

The profile characteristics module contains a specific set of blade profile sections. This program version includes BRUXEL 36, CLARK Y, Espero 20%, GOE 188, GOE 225 and NACA 0012 profiles. The profile database contains the profile image, a list of its dimensionless coordinates and profile blowdown polares in the wind tunnel at low Reynolds numbers.

The data input module accepts the parameters entered by the user and validates them in accordance with the specified rules. Invalid parameters are replaced with default parameters (by default, popular input values are set) and a warning is issued to the user.

In the aerodynamic calculation module, the basic parameters of the wind wheel are calculated. The algorithm is based on an algorithm for calculating a real windmill, presented by Professor G.Kh. Sabinin.

In the first part of the aerodynamic calculation, calculations are made of the losses of a wind wheel and dimensionless parameters of a wind turbine blade. For this, the blade is conventionally divided into five parts and differential calculations of each of its individual sections are performed. At this stage, the base of the purge polar in the wind tunnel of the selected profile is actively used.

n the second part, the calculation of the wind speed is given taking into account the set height. Here, the average annual wind speed is used, which is automatically determined or manually entered. Further, in the cycle, the dimensions correspond to the parameters of the blade and are adjusted according to the height of the mast. Thus, the lower part of the tip of the blade was 3 meters above the obstacles or the surface of the earth / water. This allows not only to reduce the turbulent effect on the Screw, but also to secure a person standing nearby.

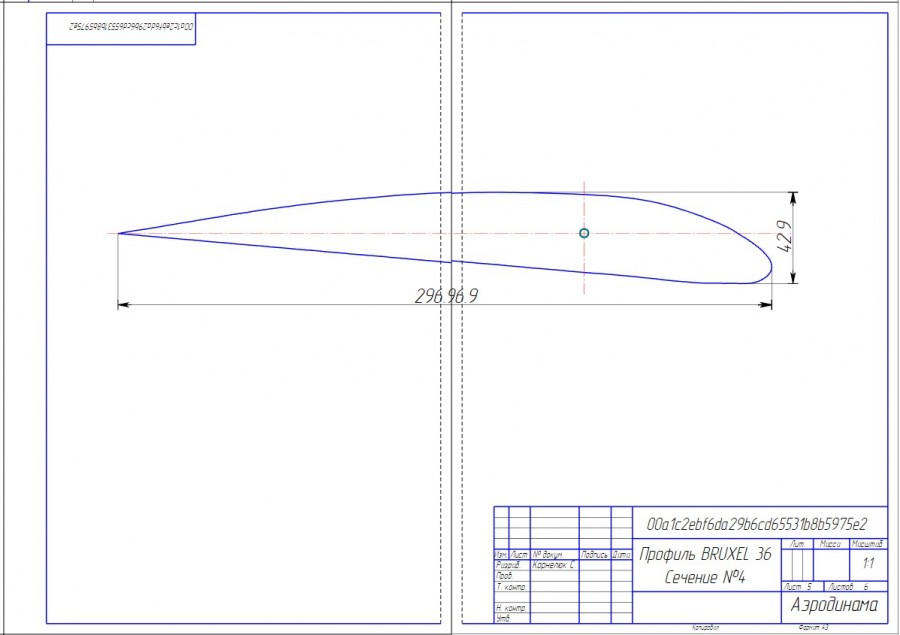

After obtaining the main dimensions of the blade, the points are calculated for constructing its sections. At this step, the dimensionless parameters of the selected profile are used.

Aerodynamic calculation allows to get the main dimensions of the parameters of the wind turbine propeller.

The wind turbine operation mode calculation module allows to predict propeller operation by such characteristics as power, revolutions per minute and torque over the entire range of selected wind speeds. The range of selected wind speeds is built from 0 m/s to the speed specified by the user as a storm. As a result, the user receives three graphs that clearly show the dependence of the selected parameters on wind speeds.

The design characteristics module is used to display the results of the calculation of the wind turbine propeller in the design wind for a given power, taking into account the efficiency of the mechanical transmission and the efficiency of the generator, if it was specified.

As a result, the user receives information about: the estimated wind speed, the diameter and radius of the wind turbine propeller, the estimated mast height, the coefficient of use of wind energy, as well as, if the generator was pulled in, the wind speed at which the wind wheel starts to rotate.

In addition, the user is informed about the calculated and extreme values of the rotations of the wind turbine propeller, the torque on the shaft and the force of the frontal pressure on the propeller.

The technical documentation module allows you to generate the result of the work of Aerodynamics in the form of PDF documents. The resulting document contains a printout of the entered and calculated data, as well as the coordinates for constructing the sections of the blade in mm, in a coordinate system oriented relative to the plane of rotation of the screw and its center. The user also has the opportunity to generate a document containing sectional drawings in 1: 1 scale. For the convenience of the user, the drawings are automatically divided into sheets of A4 format if the section size is more than one sheet of this format.

Figure shows an example of a breakdown of an automatically generated drawing into two A4 sheets. The dotted line marks the place for gluing sheets.

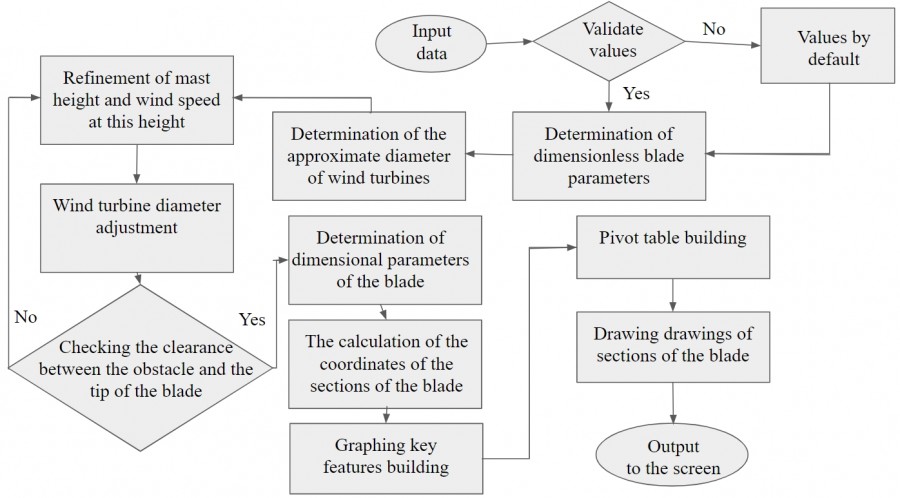

The general algorithm of the Aerodynama operation is presented in the figure.

In many countries, extending a high-voltage power line by 1 km will cost more than a small wind turbine with a low installed capacity. On the other hand, compared to diesel generators, the initial cost of wind turbines is higher, but in terms of users, it is much better in operation and does not require any fuel, lubricants and continuous monitoring.

Economic calculations for small wind turbines show their competitiveness (especially for wind turbines with a power exceeding 250 W). In an area where the average wind speed exceeds 4 m/s, the installation of wind turbines for daily electricity production of up to 1 kWh will be cheaper than using a diesel generator or expanding the grid. A wind power of 10 kW already at a wind speed of 3-3,2 m/s becomes profitable. Territories where the average annual wind speed is less than 3 m/s are not much.

The problem is still the correct forecasting of wind turbines work, the efficient utilization of wind resources and the efficient accumulation of electricity.

Aerodynamics is a tool that eliminates the problem of re-calculations of wind turbines under different wind intensity conditions. The computer calculation takes from 1 to 1.5 seconds, which significantly reduces the time of the engineer to select the required characteristics of wind turbines as opposed to manual calculations.

It is also an online, open-source web tool for anyone with a simple intuitive interface and addresses the following issues:

1. Automatic search of the average annual wind speed for a certain area and its calculation according to the aerodynamic influence of the relative position of the blades, the effect of installation height and terrain index.

2. Determination of the basic overall dimensions of the wind turbine and the height of its installation, providing a given design power.

3. Selection of the scheme that will provide the start of the wind turbine at the lowest possible wind speed.

4. Calculation of aerodynamic characteristics of blades and selection of the most optimal profile.

5. Calculation of wind energy utilization factor.

6. Conducting optimization calculations to obtain the blades sizes and their angles of installation for maximum efficiency of the wind turbine.

7. Preparation of data on the values of aerodynamic forces and mechanical moments for the entire speed range used to perform dynamic and strength calculations.

8. Preparation of design documentation for the production of blades.

9. Prediction of wind turbine modes over the entire range of predetermined wind speeds in increments of 1 m/s.

Graphical display of wind turbine modes at different wind speeds.

Serhii Korneliuk

Serhii Korneliuk