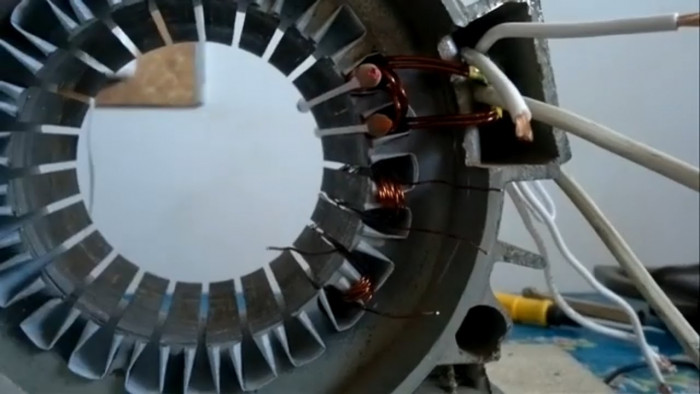

After some calculations and fitting, the magnets were placed in the stator and it became clear that the initial idea with 22 magnetic poles for 24 teeth with our magnet size (with a magnet width of 1 cm) was still unsuccessful. More poles are needed, so 26 magnets were taken. The rotor filling percentage is about 70%.

In our opinion, this is the golden mean. If this statement is true, it will help us to predict sticking and give relatively good energy.

The next step: cleaning the stator from the windings.

On different motors, windings can be removed in different ways. In our case, we will try to do everything as accurately as possible. We will dissolve the windings and bite them. Chopping with a chisel is not recommended, so as not to damage the plates themselves.

So we take the tool and proceed to "plucking."

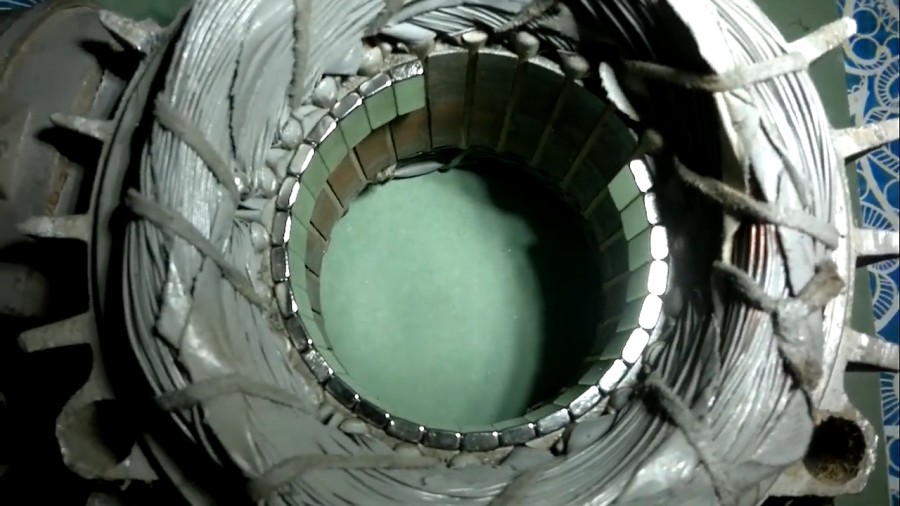

After the work done, the end of the two coils is as follows:

Further, "armed" with a chisel, they began to cut it with the help of it, since they bite for too long. In some places it is well cut down, and in some places stretches, but there is nothing wrong with that.

After chopped off half, we can already take the “grinder” with a disk with a diameter of 125 mm, which allows you to finish faster. But also do not forget that everything must be done very carefully so as not to hook the aluminum case, as excess cuts can lead to cracks in some extreme conditions. Also observe safety precautions, because a lot of small copper particles fly.

It was decided to make the second part completely "grinder". And here are some disadvantages: it is cut not at the root, and not at an angle of 90%, but work in this way is approximately 4 times faster.

First, it is necessary to make incisions, and when the “grinder” can already deepen, you can finish the process.

We draw your attention to the fact that the cut should be as even as possible and, preferably, the ends of the windings should not diverge.

The conductors should be knocked out from the more evenly cleaned side.

We take a hammer and a bolt whose diameter is as close as possible to the internal diameter of the groove. And proceed to knocking out.

Also, it is advisable to leave one not collapsed stacked coil in order to count the number of turns, wire cross-section, calculate the area and determine how much such wire will be needed for an already new cross-section.

If the coils went to expand, do not panic, you need to cut the coils as close to the iron as possible, and knock out on the side that is easier to do. You will succeed.

That's all for today.

We remind you that our wind turbine will work on charging 12 and 24 volts.

Why you can not use native windings is described in the previous article, so go and read.

Michail Lyamaev

Michail Lyamaev